How to sharpen a Global knife

I love Global knives, they are light, they stay sharp, they look good, and they are extremely easy to keep clean and affordable. So it really makes me sad to see how many of them that is ruined from bad sharpening, miss aligned edges, wrong edge formation, wrong edge bevel angle, overheated from grinding machines and belt sander, bad finish and so on. If they are sharpened the right way they are one of the best knives you could have, but with a bad sharpening job they might not be better than anything else.

This is how ordinary Global knives (not single beveled) should be sharpened:

– They should be hand sharpened on Japanese Water Stones.

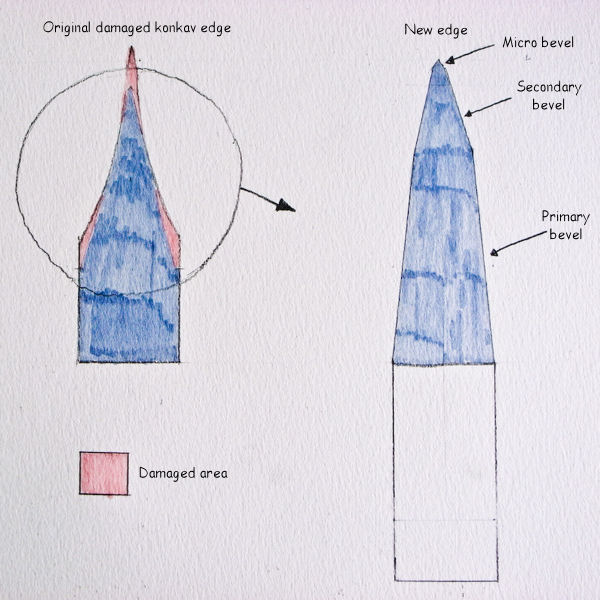

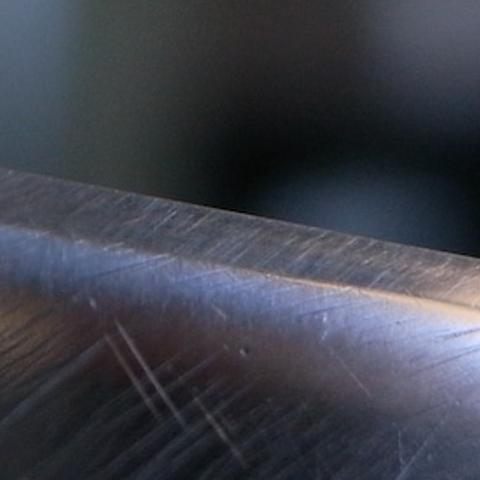

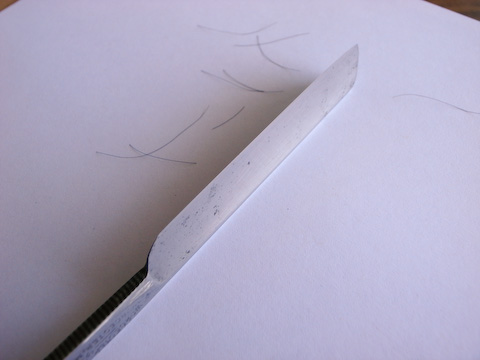

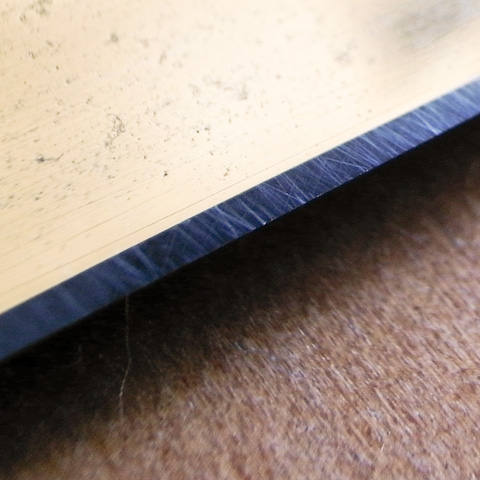

– The edge formation should be slightly convex on the back end of the edge bevel.

– The edge should have a 15° angle, but it is possible to give it a slightly steeper angle if needed.

If you follow this links to their sites, you could check it out yourselves.

Edge formation: http://www.yoshikin.co.jp/w/craftsman/index.html

Sharpening: http://www.yoshikin.co.jp/w/maintenance/maintenance_01.html

Hand sharpen performance: http://www.global-knife.com/catra/index.html

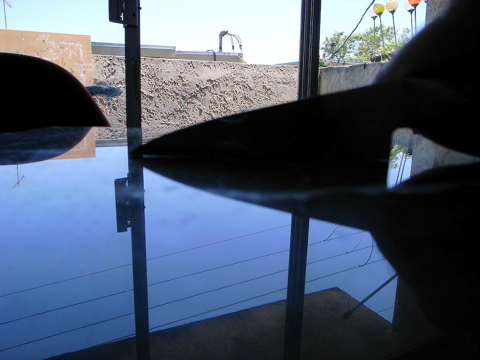

The little video above shows what performance you should be able to expect from a newly sharpened Global knife. Maybe not, if you prefer an edge with more bite, but you should at least be able to slice thin slices of tomatoes and shave with it when it is newly sharpened.

The knife in the video a customer came in with, it had be sharpened for the first time the week before of another sharpener. She told him that it wasn’t as sharp as she had expected it to be. His response was that it was sharpened to factory specs, and that a resharpened knife never could be as good, as it was when it was new. First of it wasn’t sharpened to specs, it had an uneven bevel, the bevel wasn’t convex, and the edge bevel were close to 22°, the edge was very rough and still had a burr. With some luck she might have been able to slice a thick printer paper, and maybe it was a bit sharper than when he started sharpening it, but it wasn’t gorgeously Global sharp. It is definitely possible to getting a Global knife sharper than it was when it was new, check Global’s CATRA report on the “Hand sharpen performance” link above.

The knife above I gave a little more finish than needed, just to make her happy. Anyway here is how I got it back in shape, started with DMT and Chosera #400 to clean it up and set the new bevel, after that I went straight on to bester #2000 that is one of my favorite stones, it cuts fast and gives a great edge. After that I used Blue Aoto before finishing on an uknown #6000 and a #8000 Kitayama, finally I gave it a light strop on leather loaded with Mothers Mag & Aluminum polish (be careful clean the knives several times after, that polish is definitely bad for you if left on knife) Usually I don’t strop customers knives, but thought it would be fun in this case and it definitely improve push cutting performance.

Magnus Pettersson hand sharpening, now serving the whole Westside with free pickup and delivery: Santa Monica, Brentwood, Pacific Palisades, Venice, Marina Del Rey, Culver City and West LA.

For free pickup and delivery on the Westside, call/txt 310-486-6068 or email.